More than fourteen years after building my first robot, I wanted to reflect on its design and manufacturing process. Thinking about this little guy makes me appreciate the incredible prototyping tools and technologies we have today—resources we often take for granted. Back then, designing hardware felt like an uphill battle without the convenience we enjoy now.

Quick Introduction

This robot was one of six I built in Colombia in 2011 as part of my thesis for a B.S. in Electrical Engineering. The goal of the project was to create an affordable robot suitable for swarm robotics research.

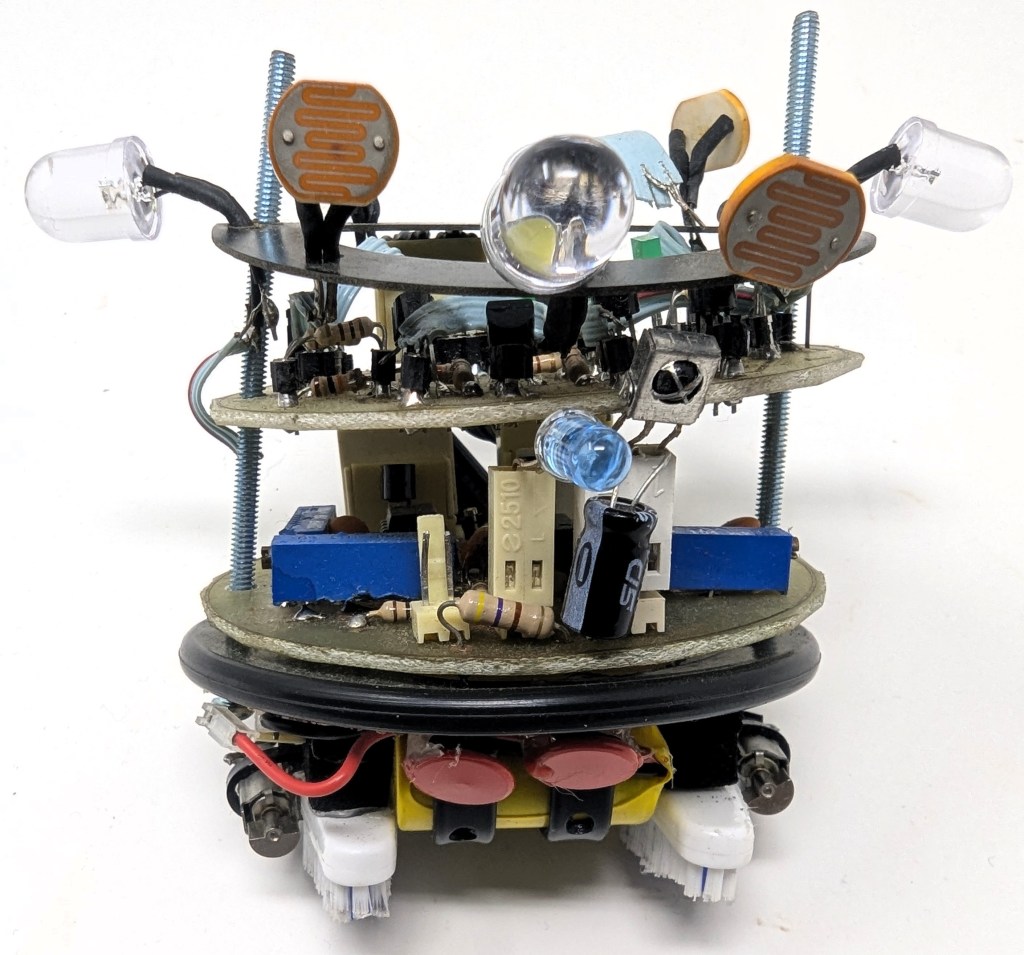

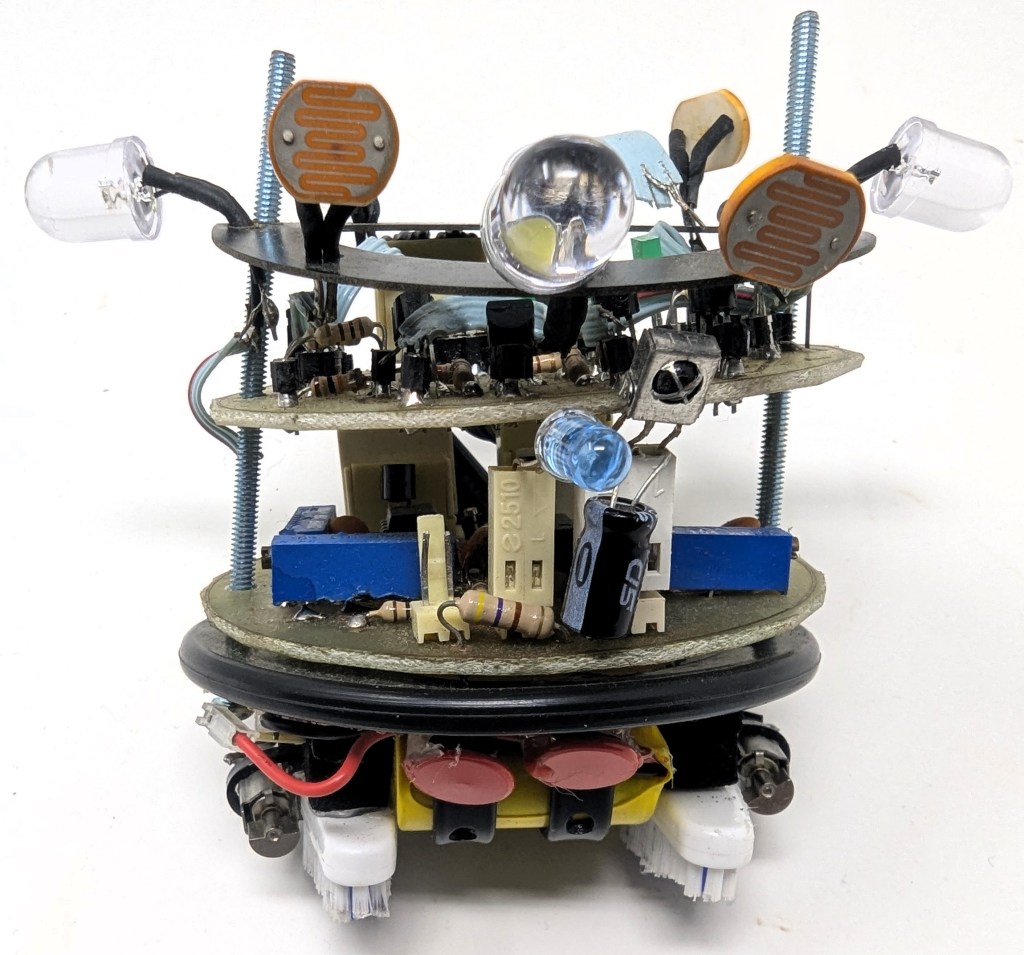

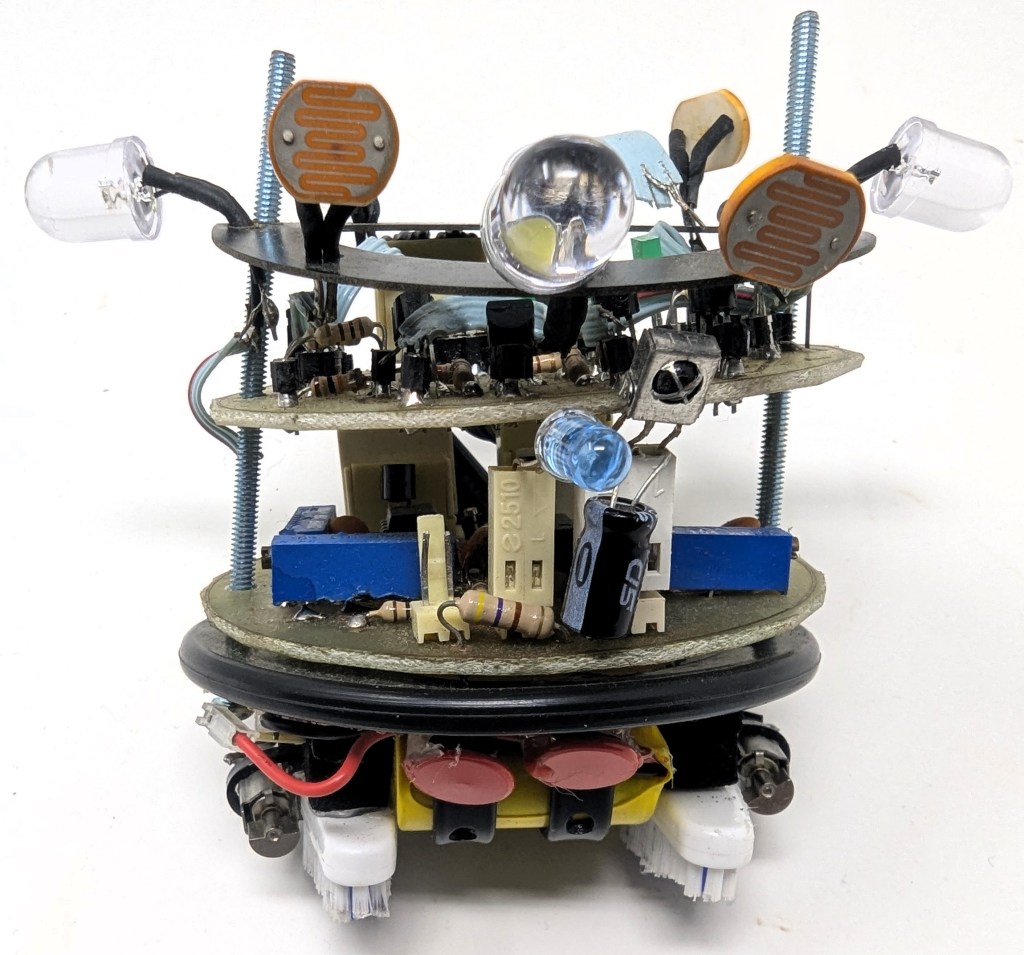

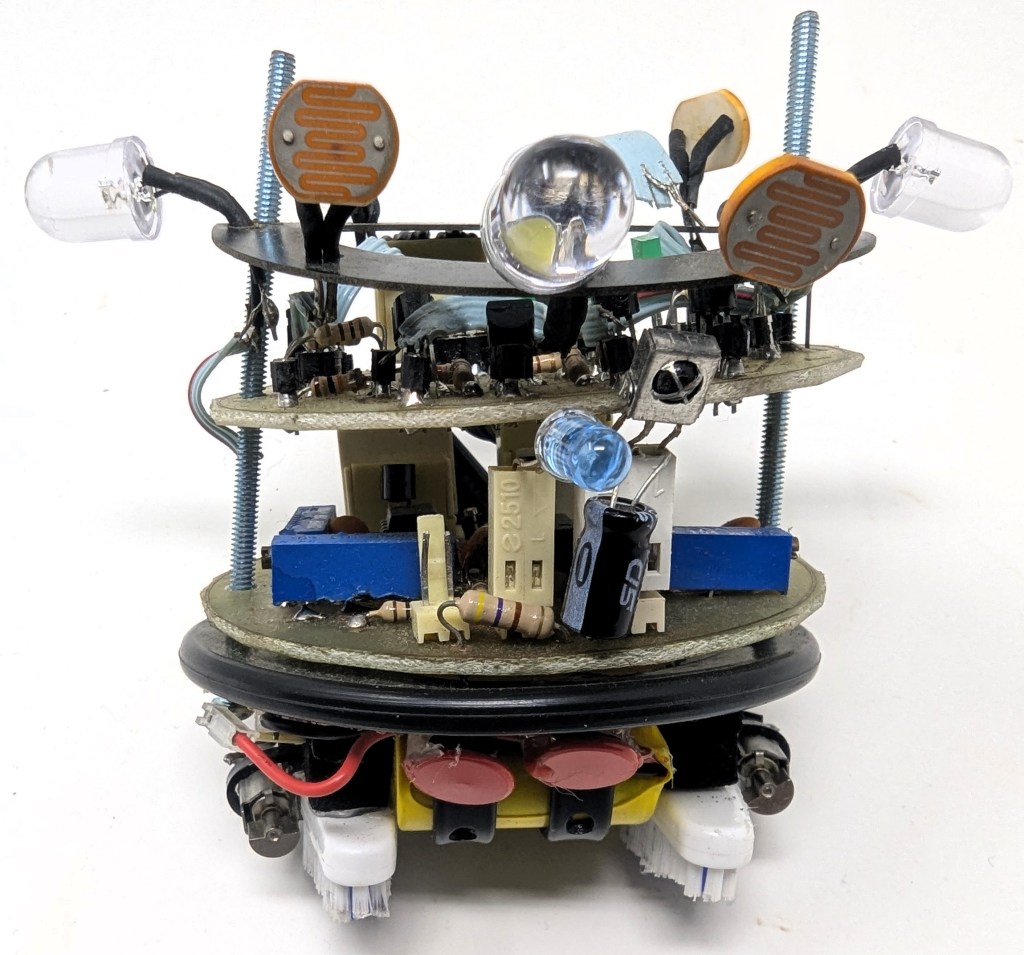

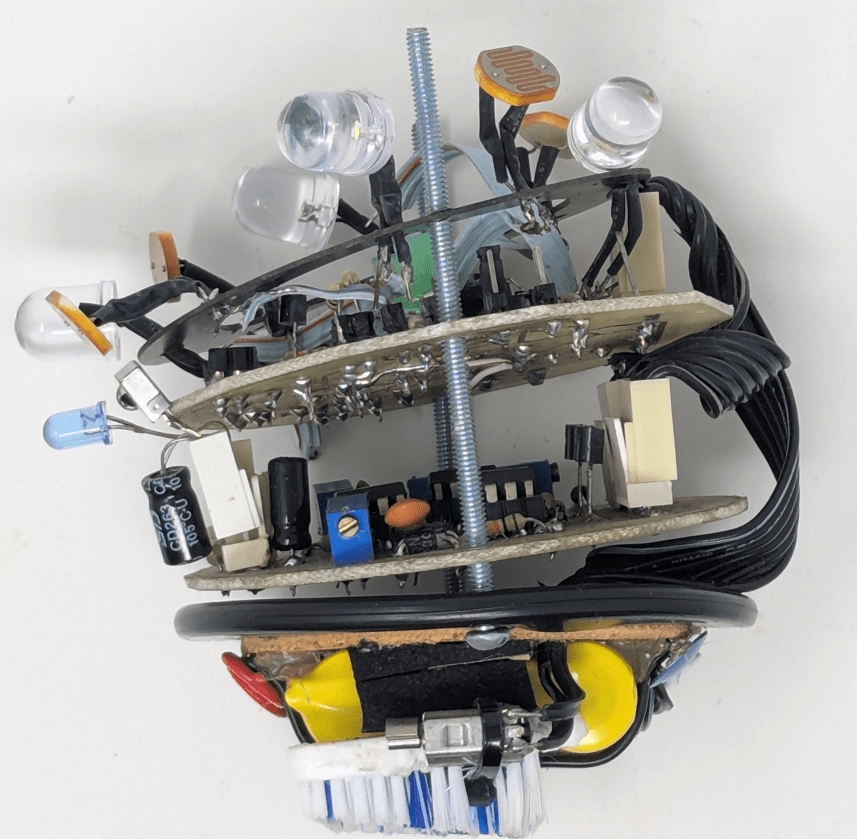

Whenever I show people this robot, I get a lot of comments about its rough construction. Its handmade look makes it feel more like something out of a tinkerer’s post-apocalyptic workshop than a sleek, modern robotics lab.

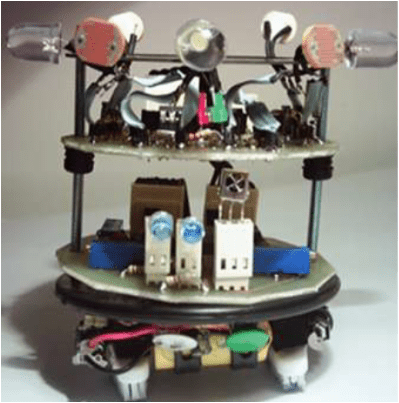

Picture from 2011, when the robots were freshly made.

Robot, 2025, 14 years after being stored in a closet

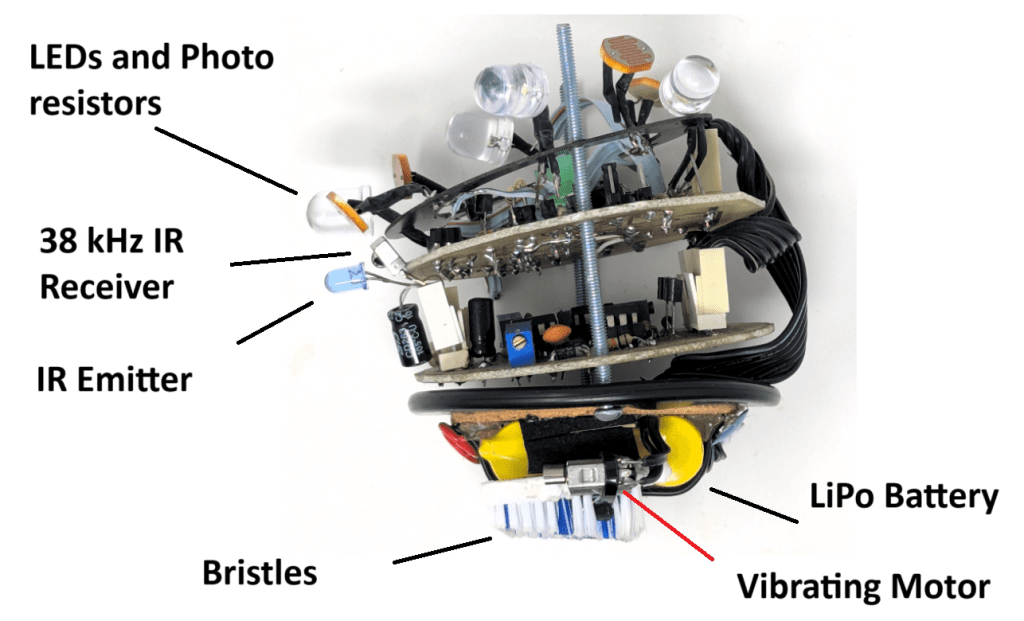

Locomotion: Differential “Bristle Robot”. Vibrating motors with toothbrushes

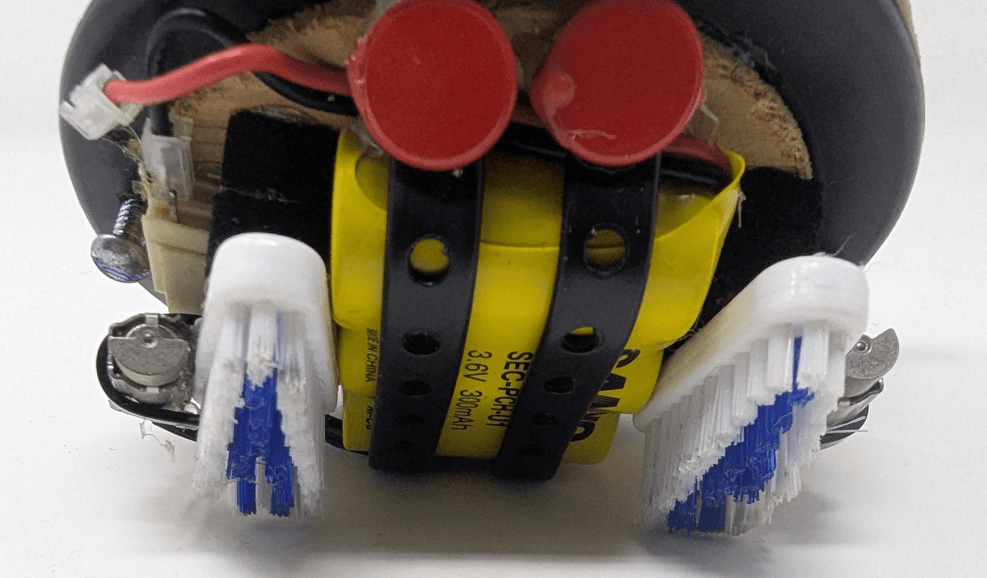

Battery: 3.6V 300mA DC Phone Battery

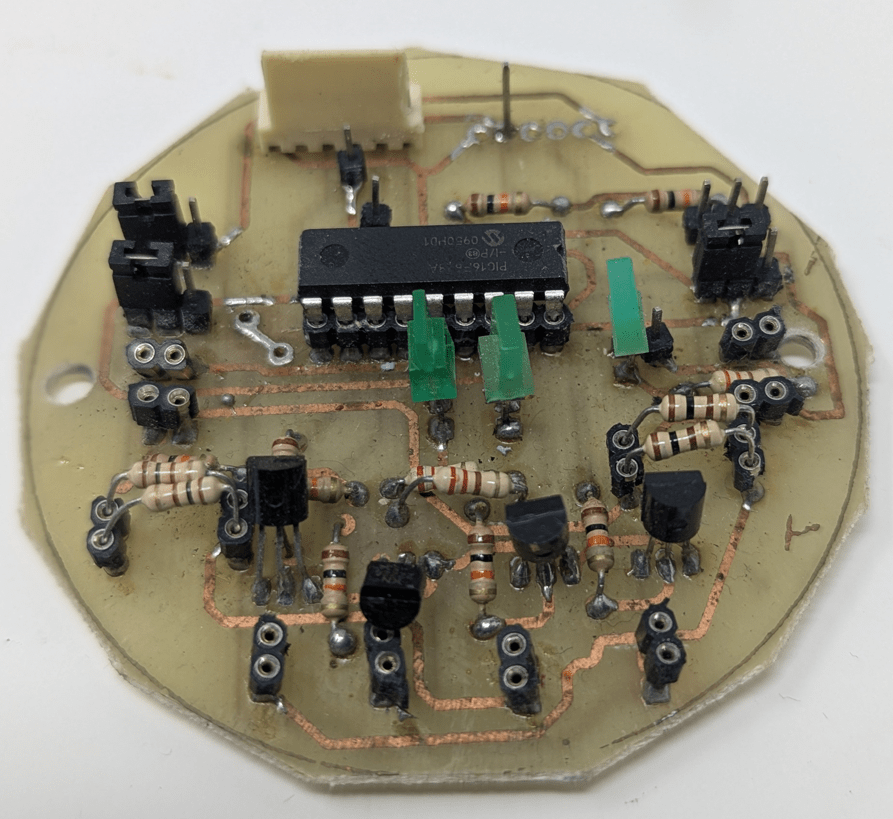

MCU: Microchip PIC 8 Bit (PIC16F628A)

Digital communication: IR emitters and 38kHz TV IR receiver. The swarm could be controlled with a TV remote, and individual robots could broadcast messages using their 38kHz IR transceivers.

Robots attracting other robots with a light

Being able to control the swarm with a TV remote, and others being able to broadcast messages with the 38kHz IR transceiver.

Hardware – Components

Reflecting on this project, I realize how access to the right components impacts hardware design flexibility. Today, platforms like DigiKey and Mouser deliver thousands of components to your doorstep in just a few days. My experience in Colombia back then was drastically different—more like a treasure hunt.

Engineering students often visited “La Novena,” a street filled with small electronics shops. These stores sold everything from basic electrical components to salvaged hardware, making it a tinkerer’s paradise. However, this also meant designing with whatever was available. Through-hole components dominated the market, which is why my robot exclusively uses them.

Hardware – PCBs

PCB fabrication was another significant challenge. Services like PCBWay or JLCPCB weren’t readily accessible to students like me. Instead, we used the toner transfer method to create PCBs manually.

For this robot, I hand-cut circular PCBs and etched the traces using toner transfer. Drilling ~100 holes per board and soldering every connection was a labor-intensive process. Since the method didn’t support vias, I soldered male header pins to connect traces between layers. With each robot requiring two PCBs, this process was a true test of patience!

Today, professionally manufactured PCBs with solder masks and silkscreens cost just a few dollars, making me appreciate modern prototyping even more.

Hardware – 3D printing/Laser Cutter/etc

The robot’s mechanical design is where I see the most room for improvement. Its flimsy wooden base and rough finish give it a very rustic look. Modern prototypes benefit from accessible tools like 3D printers and laser cutters, which offer precision and flexibility at an affordable price.

This robot, however, used whatever was available—a wooden base with a rubber gasket bumper, screws, and a salvaged LiPo battery held in place with a metal bracket. While functional, it lacked polish, and I left some tacks visible because I thought they added charm (in hindsight, probably a mistake!).

Why toothbrushes on the bottom? Vibrating motors were inexpensive and readily available, unlike DC motors for wheels. This led to the bristle robot design. I found that adding a stiff foam layer between the wooden base and the toothbrushes improved its movement.

Final Thoughts

Looking back, this robot reminds me how far technology has come and how much easier prototyping has become. Despite its rough edges, it served as the foundation for my passion for robotics and hardware design—a lesson in creativity and resourcefulness that shaped my engineering journey.